What's new in volumill™

volumill™ version 10.5 offers the most significant performance increase over any previous version of VoluMill.

This latest release delivers even better machine-tool and cutting-tool performance – increasing shop floor productivity and cost-savings

Quickly and easily program parts

Using volumill™, you'll never worry about over-engaging cutting tools or work-hardening materials. VoluMill's unique patented technology makes programming simple by automatically controlling material removal rates regardless of geometry or it's complexity. Built-in to VoluMill are all of the latest rough-milling strategies which are automatically applied when suitable and advantageous. VoluMill's unique smartpath-engine eliminates the need for guessing or having to make complex mathematical calculations. A combination of controlled material removal and industry best-practices are automatically applied.

How stunning machine-tool and cutting-tool performance is so easily achieved

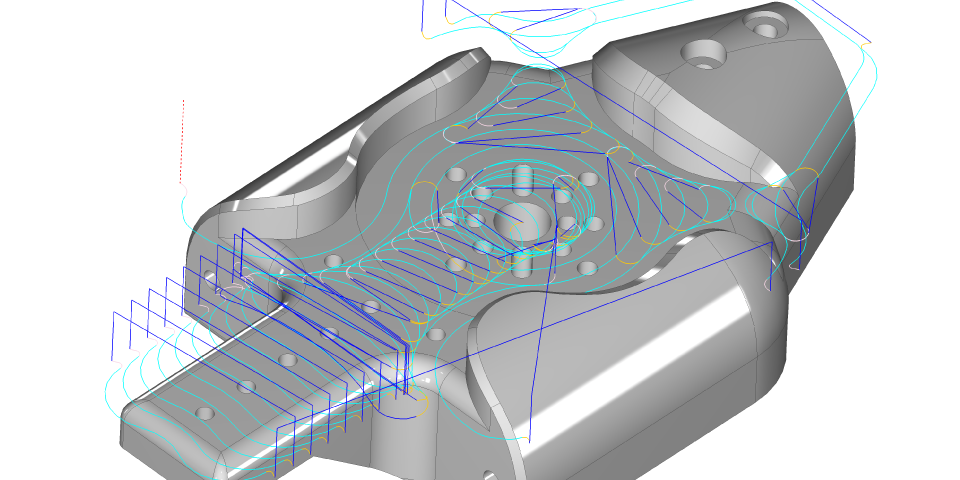

volumill™ improves the way that tools cut their way through material, using high-speed continuous tangent motion rather than sharp, interrupted movements. Field applications prove that VoluMill can safely double machine output, extend tool life, and create a much more productive competitive manufacturing enterprise in the global marketplace.

Let your machine-tools and cutting-tools perform as they were intended to

volumill™ allows programmers to use the most appropriate cutting styles and optimum feeds and speeds. This is possible because VoluMill produces toolpaths that contain no abrupt changes in direction or to the volume of material encountered; the load on the cutting tools and spindle never exceeds user-programed limits. Consequently, machines run smoothly and tools run cooler, even at much higher speeds and feeds, extending tool and machine life.

volumill™ works on any material, part, or geometry

volumill™ works on any shape, open or closed, with any number of features, and integrates with any CAM system. It plans the toolpath based on abilities designed into the machine and cutting tools. By taking advantage of the capabilities of modern machining hardware and avoiding sharp directional changes, it generates toolpaths that assure the machines and cutting tools are used at peak efficiency given existing conditions. VoluMill is ideal for any 2-axis or 3-axis part. It easily cuts pockets, steps, slots, channels and other shapes, and can handle an unlimited number of material and part boundaries and islands. It can be used with any cutting style and material, including the hardest metals.